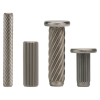

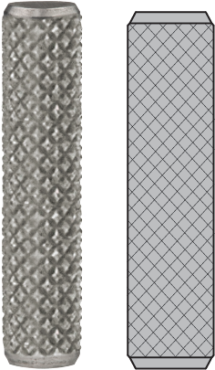

Solid Dowel, Barbed, & Knurled Pins

Solid Pins are straight, cylindrical, relatively inflexible press-fit pins. Solid Pins are commonly used to locate components in a fixed position, to maintain alignment, or to act as axles, pivots or hinges.

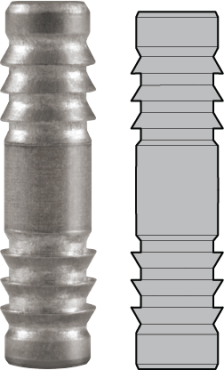

SPIROL’s Knurled Pins and Barbed Pins have raised “ridges” that interact with the host material to retain the pin within the hole. SPIROL’s Press-N-Lok™ Pin has opposing barbs on each end of the pin and is designed to permanently retain two plastic components to each other. Unlike Straight Pins and Ground Dowels that require extremely tight hole tolerances, SPIROL’s Knurled Pins are designed to be used in standard drilled holes to minimize manufacturing costs. Using this approach, SPIROL’s Solid Pins are commonly used to replace expensive machined pins. Cumbersome screws are often replaced with Knurled Pins and Barbed Pins that offer better retention and improved assembly speeds.

SPIROL minimizes cost through standardization of raw material, tooling concepts and production methodology, and investment in state-of-the-art cold heading and secondary processing technology. Our internal production processes are controlled by continuous inprocess monitors and are certified to international standards IATF 16949.

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Solid Pin assembly requirements.

Application Engineering Assistance: If you would like assistance in selecting the proper Solid Pin - including the recommended hole size, tolerance and installation method - please Request Engineering Support! We are here to help!

Solid Pin Types

SPIROL’s comprehensive standard Solid Pin line include Straight Pins, Knurled Pins, and Barbed Pins - with or without a head. Diameters range from 1.5mm / .062” (1/16”) up to 6mm / .250” (1/4”). Standard materials include low carbon steel and nickel stainless steel.

Select from the options below for more specificity about the different types of SPIROL's Solid Pins or contact us for complimentary technical support!

Don’t See What You’re Looking For?

Need help choosing the most appropriate fastening solution for your application? SPIROL's expert engineers will review your specific requirements, and design the most cost-effective Solid Pin to meet your technical and commercial needs. Let us help!

Specifications

| Material Type | Material Grade | Finishes |

| F Low Carbon Steel | UNS G10220 / C20C (1.0411) | K Plain, Oiled |

| D Stainless Steel, Austenitic (Nickel) | UNS S30500 / X4CrNi18-12 | P Passivated |

Other materials and finishes are available to order depending on the application requirements.

TO ORDER: Product Code / Diameter / Length / Material / Series Code

EXAMPLE: SLDP 4 X 20 FK KP300

Why Use a Solid Pin?

With so many types of industrial standard pins to choose from, the challenge for the designer is to select the most cost-effective pin that meets the specific application requirements. While more than one type of pin may meet certain requirements, here are some general guidelines when a Solid Pin may be most suitable:

- When a head is required for a positive stop or to retain a thin member to a thicker member of the assembly

- When a smooth, uninterrupted surface is required such as when used in conjunction with a pawl or other angular component

- When a hollow pin is not suitable such as when the designer is looking to plug a hole (i.e. Restrict passage of liquids)

- When there is a need to manually align several clearance holes

- When increased bending or shear strength is required

- When precise hole locations need to be maintained

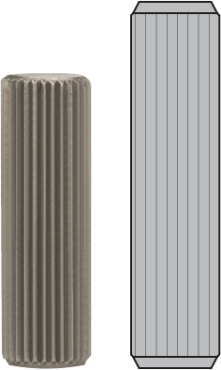

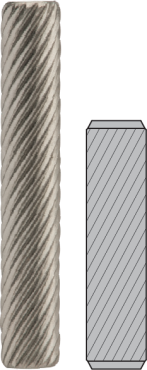

Retention Features

Solid Pins are commonly used as permanent fasteners in a wide range of applications. They are retained by the harder Solid Pin displacing material in the softer host component(s). There are two primary methods of accomplishing this:

- Press-fit: Press-fit dowels and straight pins are typically retained in the assembly by being pressed into holes that are smaller than the pin diameter. The pins are retained by compressing the host material.

- Retention features: Retention features (i.e. knurls and barbs) are often preferred over press-fit dowels because they allow for wider hole tolerances and lower insertion forces during assembly. Knurls and barbs carve into the softer host component, and displace the host material into the valleys of the knurls and barbs. This results in more frictional contact area between the pin and hole, and thus higher retention as compared to simple press-fit doweling.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

Hinge Pin in Automotive Interior Door Handle Latch Mechanism

Customer Challenge:

An automotive door handle manufacturer approached SPIROL to recommend a hinge pin that would eliminate the BSR (buzz, squeak & rattle) caused by a semi-tubular rivet they were using in their assembly.

SPIROL solution:

- SPIROL’s LP500 Latch Pin for Plastics was specifically developed for the automotive handle and latch market.

- The barbed section under the head of the LP500 Latch Pin for Plastics locks the pin into the plastic host assuring the handle pivots properly while the pin remains stationary. This also completely eliminates the concern for BSR.

- Since the pin is pressed securely into place upon insertion, all secondary operations such as riveting and peening are eliminated.

- Replacing the current Semi-Tubular Rivet with SPIROL’s LP500 Latch Pin for Plastics simplified the assembly process, improved production efficiencies, eliminated lubricants, and improved the overall product quality of the door handle.

Retention Pins in Plastic Electric Vehicle Charging Handle

Customer Challenge:

A manufacturer of electric vehicle charging handles had been experiencing high scrap rates during assembly due to screws stripping the plastic host. They wanted to replace the screws with permanent, tamper resistant fasteners that also supported lean manufacturing.

SPIROL solution:

- SPIROL Engineering recommended replacing the screws with Press-N-Lok™ Pins that were specifically designed as retention pins for plastic enclosures.

- Press-N-Lok™ Pins have barbs that provide high retention in plastics. As the pins are pressed into the plastic, the barbs displace the plastic host material. After installation, the plastic backfills behind the barbs to lock the pins in place.

- The assembly time for the Press-N-Lok™ Pins was much quicker and the assembly equipment costs was lower compared to the screws previously used.

- SPIROL's Press-N-Lok™ Pins simplified the assembly process, and eliminated scrap events associated with the installation of the screws.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 860 774 8571

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国