SPIROL® Series 2000 Vibratory Feed System

SPIROL’s Series 2000 Vibratory Feed Systems provide higher feed rates, gentler feeding, and the ability to accommodate a wider range of part configurations and materials than conventional feed systems. The advanced state-of-the-art electronic controller combines modern technology and unique features to deliver superior performance by continuously and automatically adjusting the drive system to the natural frequency of the bowl. This variable frequency technology compensates for changes in the bowl mass to ensure consistent feed rates and eliminates bowl tuning, allowing interchangeable bowls with a single drive. Additional benefits include increased energy efficiency, clockwise/ counterclockwise capability, reverse rotation, and significantly lower noise levels. The controller utilizes a touch screen interface with the capacity to store 50 recipes.

The leading edge of radial drive technology.

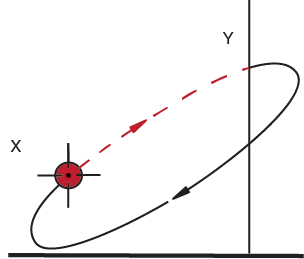

Electronically adjustable, dual axis Vibratory Feed Systems featuring the patented SPIROL Series 2000 Drive System — tuned electronically, rather than by re-springing, making setup and changeover for multiple bowls on one drive a snap! Available drive sizes are 12", 18" and 24".

The Mark VI controller is unique when compared to conventional feeder controls because it monitors the operation of the Series 2000 feed system and continuously adjusts the output drive frequency to match the natural resonant frequency of the drive unit. The controller automatically adjusts the power level and synchronizes it with the two independent axes of motion within the drive unit to achieve maximum feeding efficiency.

This system is ideal for fragile, tactile, and slippery parts.

Not sure what you need?

SPIROL's Application Engineers will design the most appropriate high-performance feeding system for your assembly requirements! Contact us today for complimentary engineering support!

Enhanced Features Include

- USB receptacle provides access for firmware updates while in the field

- Ethernet connection for remote web browser access with full functionality

- RS232 receptacle provides serial communication with queries and commands to set power levels

- Input port and cable allows for remote stop/run, track sense on/off, vertical inhibit which will idle the bowl, and feed direction

- Output port and cable allows Mark VI control of accessory equipment

- A large capacitor bank recycles energy, promoting efficiency and conserving energy effectively reducing your carbon footprint

Benefits Include

Elliptical bowl motion generated by the coordination of the two axes of motion provides the following benefits:

- Smoother, gentler feeding eliminates damage and significantly reduces noise levels

- Consistent part per minute feed rate

- Bowl interchangeability on one drive unit without the need for mechanical tuning

- Ability to discharge all product from the bowl to accommodate small batch runs

- High speeds, up to 2.5X conventional system rates

Additional Information

Remote access, multiple program feature and continuous feedback loop puts the SPIROL Mark VI Controller with Series 2000 High Performance Feed System on the leading edge in feeder technology.

The Mark VI Controller is a state-of-the-art, microprocessor-based controller for use with SPIROL Series 2000 High Performance Feed Systems. The controller optimizes feeding by constantly driving at the natural frequency of the system while also automatically adjusting output power to maintain a constant vibration amplitude.

Additional Fastener Installation Technology and Equipment

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 860 774 8571

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国