Components Produced Annually

Standard Items

Customer Applications

Global Locations

Innovative Fastening Solutions.

Lower Assembly Costs.

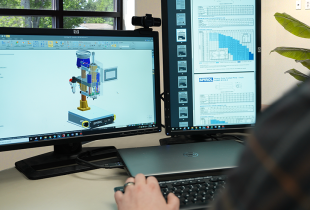

We are the leading global manufacturer of engineered fasteners, shims, installation machines, and parts feeding equipment producing over two billion components annually. In addition to high quality products, SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and global stocking facilities to simplify the logistics of delivering your product.

Partner with the Experts in Fastening, Joining and Assembly

We offer complimentary engineering support to help you design not only the engineered fastener, but also the critical recommendations for the interface between our product and your assembly. Let us help you!

Request Technical SupportQuick Product Search

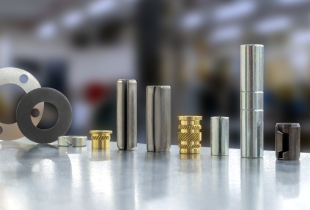

We offer a comprehensive line of standard engineered fasteners, shims and installation equipment for the total assembly solution. Standard products ship from stock!

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

Our Complimentary Application Engineering Process

When you engage with SPIROL as part of your team, we will utilize our 5-Step Process for Success to ensure that you receive the right solution in a timely manner. We will be an active participant of your team starting in the design stage - through the qualification stage – until the product is launched successfully to ensure that your quality, performance and assembly objectives are completely satisfied.

Step 1/5

Define Objectives

We work with you to define your product performance, assembly and commercial objectives. This includes gathering sample components, the drawings of the individual components and the assembly-level drawings. At this stage, we also define commercial objectives such as target product costing, product packaging / labeling, and delivery requirements.

Request Engineering SupportStep 2/5

Conduct Comprehensive Engineering Evaluation

After we gather your product, assembly and manufacturing objectives, we will conduct a comprehensive engineering evaluation. Our Application Engineers are dedicated to assisting you in determining the best solution for your particular application.

Request Engineering SupportStep 3/5

Present Technical and Commercial Proposal

We will provide you with a formal technical and commercial proposal, including prototypes for evaluation in your assembly. The proposal will detail other products that were considered for your application, and ultimately why the recommended part is the optimum solution.

Request Engineering SupportStep 4/5

Deliver Complete Assembly Solution

If installation equipment is involved, we can also design a fixture to hold and align the components during insertion. We build, test, install and certify the machine – as well as educate your operators and maintenance personnel.

Request Engineering SupportStep 5/5

Exceed Your Expectations

We plan production to meet your delivery requirements and will ship certified products anywhere in the world – on time.

Request Engineering SupportApplication Success Stories

Trigger Pin in Surgical Stapler

Customer Challenge:

A leading medical device manufacturer approached SPIROL for assistance in designing a self-retaining trigger pin that eliminated cracking of the plastic yoke within the surgical stapler.

SPIROL solution:

- SPIROL Engineers recommended a Light Duty Coiled Spring Pin which was designed specifically for plastic assemblies to ensure the perfect balance of strength and flexibility.

- Coiled Pins are easy to install and exert low stress on the hole after installation, yet they provide exceptional retention.

- In addition to recommending the most appropriate pin, SPIROL Engineers also recommended the hole sizes for each of the retaining locations to make sure that the assembly functioned properly over the life of the assembly.

- SPIROL’s Coiled Spring Pin eliminated the cracking of the plastic yoke, enhanced the function of the trigger, and improved the overall quality of the surgical stapler.

Retention Pin in Plastic Electric Vehicle Charging Handle

Customer Challenge:

A manufacturer of electric vehicle charging handles had been experiencing high scrap rates during assembly due to screws stripping the plastic host. They wanted to replace the screws with permanent, tamper resistant fasteners that also supported lean manufacturing.

SPIROL solution:

- SPIROL Engineering recommended replacing the screws with Press-N-Lok™ Pins that were specifically designed as retention pins for plastic enclosures.

- Press-N-Lok™ Pins have barbs that provide high retention in plastics. As the pins are pressed into the plastic, the barbs displace the plastic host material. After installation, the plastic backfills behind the barbs to lock the pins in place.

- The assembly time for the Press-N-Lok™ Pins was much quicker and the assembly equipment costs was lower compared to the screws previously used.

- SPIROL's Press-N-Lok™ Pins simplified the assembly process, and eliminated scrap events associated with the installation of the screws.

Mechanical Clutch in Heavy Duty Right Angle Drill

Customer Challenge:

The lead engineer at a prominent hand and power tool company contacted SPIROL for help determining the best Disc Spring design for a new lightweight, compact, and portable Heavy Duty Right Angle Drill.

SPIROL Solution:

- SPIROL Engineering designed two special Disc Springs stacked in series to meet the specific force and deflection requirements.

- Disc Springs offer a higher load capacity in less space as compared to conventional coil springs which enables the designer to make the tool more compact.

- Unlike Belleville Washers that are mostly used in static applications, Disc Springs provide unparalleled predictability, reliability and fatigue life in highly dynamic applications.

- By partnering with SPIROL and incorporating our recommendation, the customer minimized costly development time and confidently launched their new high-quality drill to the market.

Alignment Dowels in Lower Engine Block

Customer Challenge:

A leading automotive manufacturer approached SPIROL for a cost-effective solution to precision align the lower engine block to the primary engine block.

SPIROL Solution:

- SPIROL's GD100 Ground Hollow Dowels are used where centerline tolerance and precision alignment are required as they maintain critical alignment within 20 µm.

- GD100 Ground Hollow Dowel reduce weight by over 50% as compared to the same size Solid Dowel.

- SPIROL's recommendation resulted in over $100,000 in annual cost savings as compared to other alignment options considered.

Conveyor Spacers

Customer Challenge:

The lead engineer at an industrial conveyor manufacturing company approached SPIROL to help resolve an issue caused by low quality plastic tubing used to separate skate wheel rollers from each other and from the conveyor walls.

SPIROL solution:

- SPIROL's Application Engineers recommended replacing low cost, low quality plastic tubing with SPIROL's CS100 Conveyor Spacers

- CS100 Conveyor Spacers are stronger than plastic tubing and competitively priced.

- SPIROL's proprietary roll forming process enables custom lengths produced with no tool charges and fast turnaround times.

- By partnering with SPIROL, the conveyor manufacturer was able to improve the quality of the assembly while concurrently controlling costs and inventory.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 860 774 8571

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国