Alignment Dowels & Bushings

SPIROL’s roll formed Alignment Dowels & Bushings are designed to meet one or more of the following objectives:

- Align / Locate mating components,

- Eliminate drilling of a separate bolt hole,

- Protect bolts from shear loading, and/or

- Maintain joint integrity

SPIROL offers (3) different options for Alignment Dowels / Bushings - each one designed to simplify the assembly process and reduce the overall cost of manufacturing.

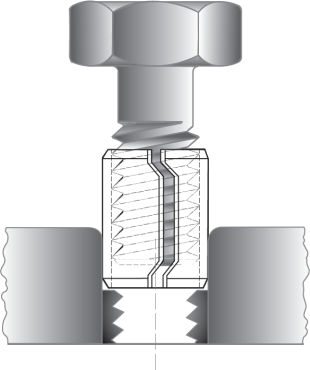

The spring-type design of the DB100 Dowel Bushings and SD200 Spring Dowels offers substantial cost savings over inflexible alignment options as the flexible diameter allows for a larger hole tolerance and thus eliminates the need to precision hone the hole. In addition, the hollow design permits a fastening screw or bolt to pass through the inside diameter eliminating the need to drill a separate hole.

When more exacting alignment is required, a precision-honed hole is required along with a precision Ground Dowel. SPIROL's GD100 Ground Hollow Dowels are designed to be direct replacements for standard Ground Solid Dowels per ISO 8734. GD100 Ground Hollow Dowels meet precision alignment requirements with significant weight savings over a solid equivalent.

If installation equipment is required, SPIROL also offers a comprehensive line of Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your assembly requirements.

Application Engineering Assistance: If you would like assistance in selecting the proper Alignment Dowel / Bushing for your application, including the recommended hole sizes and tolerances, please Request Technical Support! We are here to help!

Dowel Bushings & Spring Dowels

Ground Hollow Dowels

Alignment Dowel / Bushing Types

SPIROL’s standard Alignment Dowels and Bushings include (2) different types of Spring Alignment Dowels: DB100 Dowel Bushings and SD200 Spring Dowels, and the GD100 Ground Hollow Dowel for precision alignment. DB100 Dowel Bushings are designed to be used in conjunction with bolt diameters ranging in size from 6mm (.250") up to 16mm (.500"). SD200 Spring Dowels are designed for use in hole diameters ranging from 6mm up to 12mm. GD100 Ground Hollow Dowels are designed to be used in hole sizes ranging from 6mm up to 16mm.

Don’t See What You’re Looking For?

Need help choosing the most appropriate locating / alignment solution for your application? SPIROL's Application Engineers will review your specific requirements, and design the most cost-effective Alignment Dowel / Bushing to meet your technical and commercial needs. Let us help!

Specifications

| Series | Material Type | Material Grade | Finishes |

| DB100, SD200 | B High Carbon Steel | UNS G10700 / G10740 C67S (1.1231) / C75S (1.1248) |

K Plain, Oiled |

| GD100 | F Low Carbon Steel | UNS G10220 / C20C (1.0411) | K Plain, Oiled |

Other materials and finishes are available to order depending on the application requirements.

TO ORDER: Product Code / Diameter / Length / Material / Series Code

EXAMPLE: BUSH 10 X 25 BK DB100

Design Guidelines

SPIROL has guidelines for how to properly design the Dowel Bushing, Spring Dowels and Ground Hollow Dowels into your application including:

- Doweling for permanent positioning

- Fixing relative location of components

- Precise holes

- Maximum tolerance holes

- Centerline tolerancing

- Blind and stepped holes

- Joint integrity

Features and Benefits

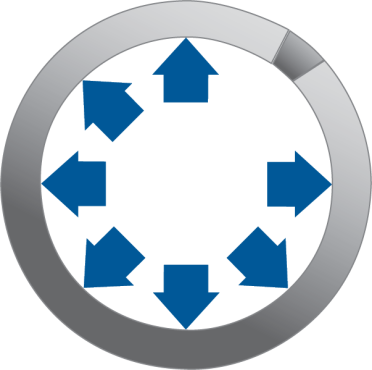

SPRING ACTION: The diameter of DB100 Dowel Bushing and SD200 Spring Dowel is slightly larger than the hole. The spring action of SPIROL's Alignment Dowel / Bushing allows it to be installed into a drilled or cored hole and assume the diameter of the hole. It is self-retained once installed.

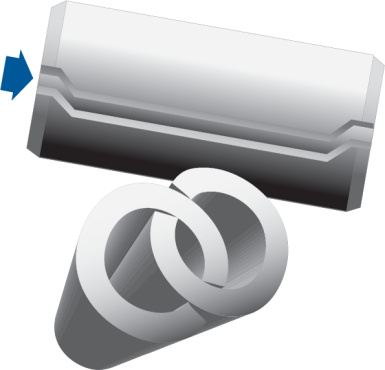

STAGGERED SEAM: The staggered seam prevents interlocking, making Dowel Bushings & Spring Dowels suitable for automatic feeding and eliminating the need to separate them during manual assembly.

CLOSED SEAM: The closed seam of GD100 Ground Hollow Dowels also prevents interlocking making these precision Hollow Alignment Dowels suitable for automatic feeding.

LEAD-IN CHAMFERS: The beveled chamfer around the entire periphery is designed to facilitate ease of insertion and to avoid skiving of the Alignment Dowel / Bushing during installation.

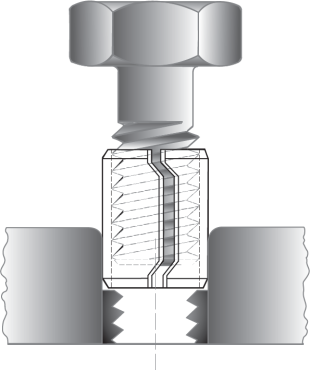

CONTROLLED INSIDE DIAMETER: The ID of the DB100 Dowel Bushing is designed to provide clearance for a bolt through the Bushing for the purpose of fastening the aligned components together. This isolates the bolt from the shear loading and increases the joint integrity. It also eliminates the cost of a separate hole.

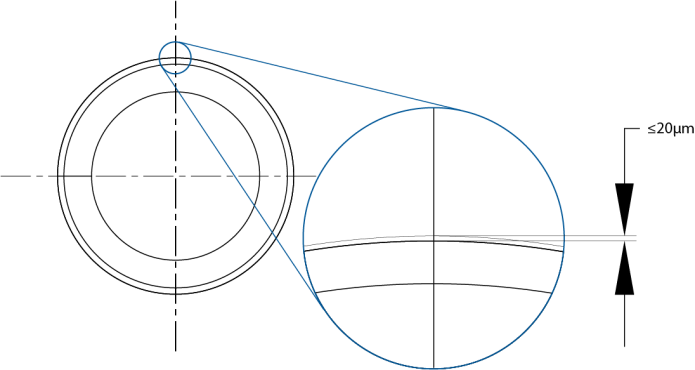

PRECISION GROUND OD: Precision ground outside diameter of the GD100 Ground Hollow Dowel maintains critical alignment within 20µm.

HOLLOW DESIGN: The hollow feature offers weight savings over Solid Dowels and clearance for bolts, fluids, or gases.

Common Alignment Dowel / Bushing Applications

Common Dowel & Bushing Applications Include:

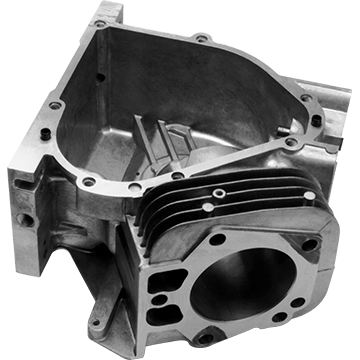

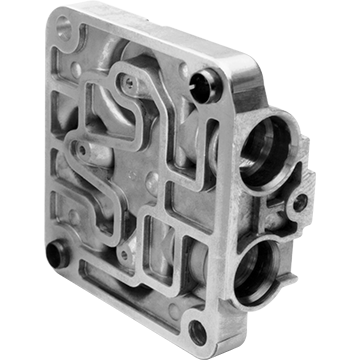

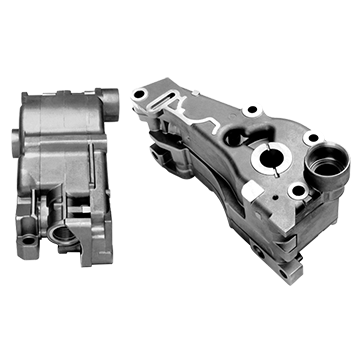

- Engine Housings

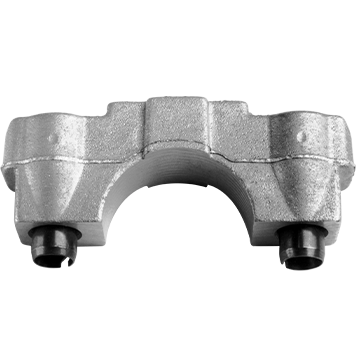

- Engine Cam Shaft Caps

- Switch Housing Assemblies

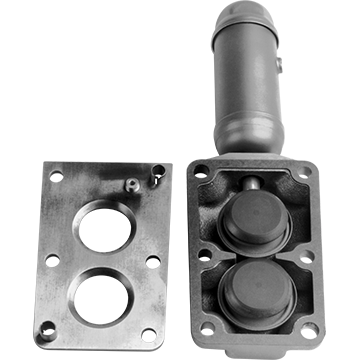

- Intake Manifolds

- Oil Pump Housings

Take advantage of SPIROL's complimentary Application Engineering support to help you select the proper Alignment Dowel and Bushing to meet both your technical and commercial requirements.

Installation Technology for Dowels and Bushings

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of installation equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

Precision Alignment Dowels in Lower Engine Block

Customer Challenge:

A leading automotive manufacturer approached SPIROL for a cost-effective solution to precision align the lower engine block to the primary engine block.

SPIROL solution:

- SPIROL's GD100 Ground Hollow Dowels are used where centerline tolerance and precision alignment are required as they maintain critical alignment within 20 µm.

- GD100 Ground Hollow Dowel reduce weight by over 50% as compared to the same size Solid Dowel.

- SPIROL's recommendation resulted in over $100,000 in annual cost savings as compared to other alignment options considered.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 860 774 8571

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国