Slotted Spring Pins

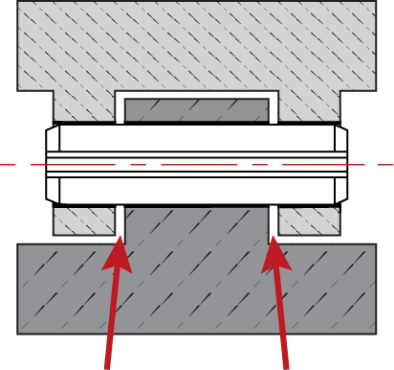

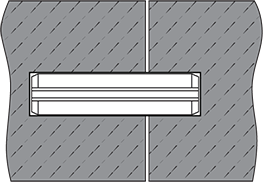

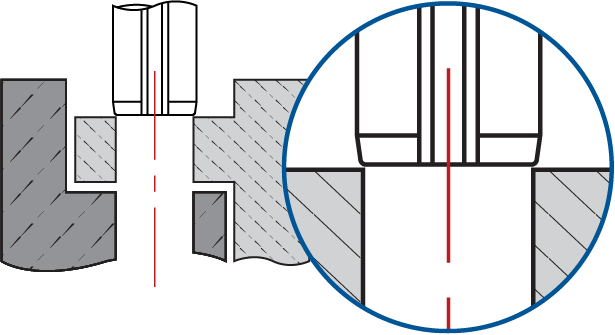

Slotted Spring Pins are general purpose components commonly used in numerous fastening applications. Sometimes referred to as Roll Pins, Rolled Pins, Split Pins, C-Pins, Tension Pins or simply Spring Pins, Slotted Pins are headless hollow tubes with a longitudinal slot down the entire length with chamfered or round ends to aid installation. Slotted Pins are produced to a controlled outside diameter slightly greater than the holes in which they will be installed. The primary spring action of the Slotted Pin is focused on the area opposite the slot as the two halves of the pin compress during installation. Once installed, the pin applies continuous pressure towards the sides of the hole wall. This flexibility allows Slotted Pins to accommodate wider hole tolerances than rigid Solid Pins which results in reduced manufacturing costs of the component.

SPIROL offers Slotted Spring Pins in both metric and inch sizes ranging in diameter from 1.5mm / .062” (1/16”) to 12mm / .500” (1/2”) in high carbon, nickel stainless steel and chrome stainless steel. Select from our expansive standard offering, or take advantage of our complimentary Application Engineering support and allow us to work with you to help determine the most appropriate Slotted Pin for your specific application and assembly needs!

If installation equipment is required, SPIROL also offers a standard comprehensive line of Pin Installation Equipment from manual to fully automatic modules, with or without out fixturing, to support your Slotted Pin assembly requirements.

Slotted Pin Types

SPIROL’s Slotted Spring Pin offering consists of 1) SPIROL Standard Metric, 2) SPIROL Standard Inch and Slotted Pins per 3) ISO 8752. While SPIROL manufactures ISO 8752 Slotted Pins, SPIROL Standard Slotted Spring Pins have a slot width narrower than the wall thickness and thus do not nest or interlock. This feature, combined with a smaller expanded (pre-insertion) diameter, results in a number of advantages for SPIROL Standard Slotted Pins compared to ISO 8752 pins including lower insertion force, longer fatigue life and no interlocking.

Select from the options below for more specificity about SPIROL's Slotted Spring Pin offering or contact us for complimentary technical support!

SPIROL also offers Slotted Pins certified to military standards (MS/NASM and NAS), and for unique applications, we have extensive experience with special materials such as beryllium copper and 316 stainless steel.

Don’t See What You’re Looking For?

Need help choosing the most appropriate fastening solution for your application? SPIROL's expert engineers will review your specific requirements, and design the most cost-effective Slotted Spring Pin to meet your technical and commercial needs. Let us help!

Specifications

| Material Type |

Material Grade |

Hardness, Vickers |

Finishes |

|

| SPIROL Standard | ISO 8752 | |||

| B High Carbon Steel | UNS G10700 / G10740 C67S (1.1231) / C75S (1.1248) |

HV 458 - 560 | HV 420 – 520 |

K Plain, Oiled

T Mechanical Zinc |

| D Stainless Steel, Austenitic (Nickel) | UNS S30200 / S30400 18-8 (1.4310) |

Work Hardened | Work Hardened | |

| C Stainless Steel, Martensitic (Chrome) | UNS S42000 X30Cr13 (1.4028) |

HV 423 - 544 | *HV 440 – 560 | |

Other materials and finishes are available to order depending on the application requirements.

* Made to order

TO ORDER: Product Code / Diameter / Length / Material / Finish

EXAMPLE: SLTP 6 X 32 BK

Why SPIROL Should Be Your Vendor of Choice for Slotted Spring Pins

SPIROL Standard Slotted Pins have a slot width narrower than the wall thickness and thus do not nest or interlock. This feature combined with

- SPIROL has over 70 years of experience in producing high quality pins with full lot traceability back to the raw material. Raw materials are RoHS, REACH, Conflict Mineral and DFARS Compliant.

- SPIROL has a global footprint with a physical presence in the US, Canada Mexico, Brazil, England, France, Germany, Spain, Poland, Czech Republic, China and South Korea.

- SPIROL's production facilities are IATF 16949, ISO 9001 and ISO 14001 certified. The customer is assured that each shipment is from the same source produced on the same equipment to the highest quality standard.

- SPIROL is a direct supplier to the automotive companies as well as to the tier 1 and 2 companies in the automotive industry and is fully versed in the high standards and demands of that industry.

- SPIROL is the only company that standardizes and inventories both metric and imperial sizes.

- SPIROL is large enough to invest in state-of-art equipment necessary to meet today's production and quality standards, but small enough to have the flexibility to meet the customer's unique needs.

- SPIROL has the widest range of product, generally ships from stock, and has the ability to respond to unplanned demands quickly.

- SPIROL's sales engineers and engineering staff partner with each customer to determine the best solution to meet the customer's performance and assembly needs or to resolve a current problem.

- SPIROL has expertise in assembly and installation of pins with a standard line of state-of-the-art Pin Insertion Machines - from manual to fully automatic modules.

Common Slotted Pin Applications

Common Slotted Pin Applications Include:

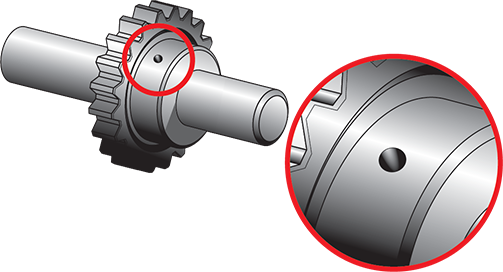

- Fastening / Retention Pins

- Hinge Pins

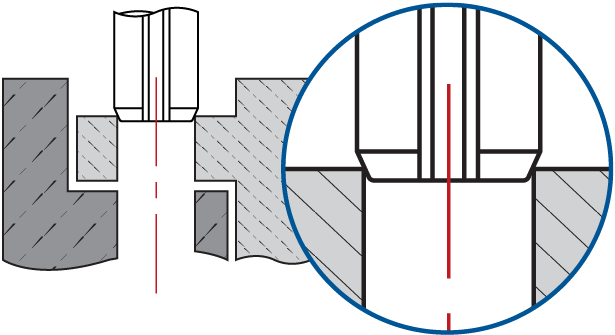

- Locating Pins / Alignment Pins

- Hub / Shaft Connection

- Stop Pins

Take advantage of SPIROL's complimentary Application Engineering support to help you select the proper Slotted Spring Pin to meet both your technical and commercial requirements.

Why SPIROL Standard vs ISO Slotted Pins?

SPIROL manufactures two types of Slotted Spring Pins: 1) SPIROL Standard Slotted Pins and 2) ISO 8752 Slotted Pins. SPIROL Standard Slotted Pins offer significant advantages as compared to ISO 8752 Slotted Pins. While both SPIROL Standard Slotted Spring Pins and ISO 8752 Slotted Pins can be effective in an assembly, SPIROL Standard Slotted Spring Pins are easier to install and superior in form, fit, and function.

- Smaller Chamfer - SPIROL Standard Slotted Spring Pins specify a maximum chamfer diameter whereas ISO 8752 does not. The maximum chamfer diameter ensures clearance on either side of the pin to facilitate installation into the hole.

- Lower Insertion Force - SPIROL Standard Slotted Pins are installed on average with 40% less force than the equivalent ISO 8752 Slotted Pin.

- Non-Interlocking - ISO 8752 Slotted Spring Pins are prone to interlocking. SPIROL Standard Slotted Spring Pins are designed such that they can not interlock.

- Higher Shear Strength - SPIROL Standard Slotted Pins provide greater shear strength than ISO 8752 Slotted Pins.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automated work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 860 774 8571

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国