Metal Spacers

SPIROL tubular Spacers are used as standoffs, distance bushings, sleeves, axles, and pins. They replace more expensive spacing options of cut-off tubing, tubes, ferrules, grommets and turned parts. SPIROL Spacers are formed into closed seam tubes from cold rolled strip. The component cost savings are achieved through:

- Use of SPIROL’s proprietary, highly flexible and efficient production technology.

- SPIROL’s roll-formed tubular Spacer design has tolerances that meet typical application requirements for spacing components apart from each other. This prevents unnecessarily close tolerances associated with manufacturing technologies required to produce more expensive alternative products such as cut tubing, machined bushings, etc.

A typical application for a tubular Spacer is to separate two components in an assembly joined by a bolt, rivet or rod passed through the inside diameter of the Spacer. The inside diameter of the Spacer is designed for a clearance fit over the bolt.

While SPIROL offers distinct diameter and length combinations in the product catalog, intermediate lengths can often be produced quickly, without any special tooling due to SPIROL's proprietary manufacturing process.

SPIROL's standard range of roll formed tubular Spacers includes both metric and inch specifications in a variety of diameters and lengths. Most standard diameters are available in two wall thickness options, standard wall and heavy wall, to accommodate specific application strength and bearing requirements.

- SP100 Standard Wall Spacers are typically used in static applications without excessive external forces acting on the joint. SP100 Standard Wall Spacers are available in metric and inch in sizes ranging from 3mm to 20mm / #4 to .750" in low carbon steel with ArmorGalv® finish. SP100 standard wall Spacers are also available to order in austenitic stainless steel and aluminum.

- SP150 Heavy Wall Spacers have greater compression strength and additional bearing surface. The additional bearing surface is often used to prevent witness marks or indenting when the Spacer is clamped between soft materials. SP150 Heavy Wall Spacers are available in metric and inch sizes in sizes ranging from 3mm to 16mm / #4 to .750" in low carbon steel with ArmorGalv® finish. Additional materials and finishes are available upon request.

The benefits of using SPIROL's standard tubular Spacers are as follows:

- Reduced cost and no tooling charges — particularly in low- or medium-volume applications.

- SPIROL's extensive inventory of standard tubular Spacers allows for just-in-time delivery and reduced inventories.

- No excess components at the end of a production run.

- SPIROL’s expansive standard tubular Spacer size range meets most application requirements and eliminates the need for custom-designed parts.

- The standard finish for SPIROL's Spacers is ArmorGalv®. ArmorGalv® is a zinc alloy thermal diffusion coating that offers over 1,000 hours of salt spray protection with full coating on the ID and OD of the part with no insignificant surfaces. Read more about The Features and Benefits of ArmorGalv® Thermal Zinc Diffusion coating.

Application Engineering Assistance: If you would like assistance in selecting the proper tubular Spacer for your assembly, please Request Engineering Support! We are here to help!

Spacer Types

The nominal diameter of SPIROL's tubular Spacers is designed around the size of the bolt passing through the inner diameter of the Spacer. Spacers are available in two standard wall thicknesses, standard wall and heavy wall, to meet the bearing surface and columnar strength requirements for each application.

SPIROL also offers Spacers designed for specific applications such as conveyors and garage doors, and custom tubular Spacers with special diameters, lengths, materials, finishes as well as in custom configurations to meet unique requirements are available upon request.

Don’t See What You’re Looking For?

Need help choosing the most appropriate tubular Spacer for your application? SPIROL's expert engineers will review your specific requirements, and design the most cost-effective Spacer to meet your technical and commercial needs. Let us help!

Standard Material

Low Carbon Steel

Low carbon steel is the most economical material to manufacture roll formed Spacers from in the absence of any plating or coating. Additional coatings and finishes can be applied to low carbon steel to improve corrosion resistance.

Standard Finishes

Plain, Oiled

The most economical standard finish is a thin coating of oil that provides corrosion resistance during storage and shipping.

ArmorGalv®

ArmorGalv® is a zinc alloy thermal diffusion coating covered by ASTM A1059M-08(2013). SPIROL recommends ArmorGalv® for Spacers for many reasons; chief among them being uniform deposition of coating on all surfaces of the part. There are no insignificant surfaces and the entire inner diameter receives full coating and protection. ArmorGalv® offers a minimum of 1,000 hours of corrosion resistance to red rust, and due to its slightly porous surface, it will retain paint and other coatings in the event that the complete assembly requires subsequent painting, power coating, etc. Compared to some stainless steels, ArmorGalv® is an ideal coating for some of the most aggressive environments such as marine, automotive, mining and industrial manufacturing.

SPIROL is a licensee of ArmorGalv®, a registered trademark of Distek N.A LLC

Special Material

Austenitic Stainless Steel

Austenitic stainless steel provides excellent corrosion protection against normal environmental conditions. It withstands fresh water and atmospheric marine conditions very well, and is suitable for many other industrial conditions including acidic environments.

Aluminum

Aluminum is lightweight, lead free, and has sufficient columnar strength for many non-critical applications. Aluminum is 1/3 the weight of steel, and does not require any supplemental coatings or platings to provide the necessary corrosion protection in most environments.

Electroplated Zinc

This finish consists of a minimum of 5μm (.0002”) thick electrodeposited zinc with a clear trivalent passivation topcoat. Zinc plate is primarily used for cosmetic purposes as this finish yields a bright, silvery appearance on the outside surfaces of the Spacer. Zinc plating is also commonly used to prevent galvanic corrosion. The major drawback to electroplated zinc on Spacers is that coverage on the inner diameter is limited to one diameter’s length of “throw” of the plating. If atmospheric corrosion protection is required throughout the entirety of the part, ArmorGalv® should be considered instead of zinc plate.

Spacer Applications

SPIROL's butted seamed, tubular Spacers are used to replace more costly options for spacing in a variety of applications.

Application Success Stories

Metal Spacer in Automotive Chassis Frame Bracket

Customer Challenge:

An automotive chassis manufacturer was originally using cut tubing as a spacer to support two plates in an automotive front end assembly. The tubing was cut to the proper length, placed between the two plates and then welded in place. In the process of cutting the tubing to length, a burr is left on the ID of the cut tubing. In order to meet the burr free quality requirements, a secondary operation of deburring the ID needed to be added to the process. This adds a great deal of cost to the cut tubing. The manufacturer approached SPIROL to see if there was a more cost effective method to space the two plates from each other.

SPIROL solution:

- SPIROL Engineering recommended a standard, butted-seam Spacer to replace the more expensive cut tubing in this application.

- SPIROL's roll-formed tubular Spacers have clean cut, square ends, therefore no secondary operations are required to ensure a burr free part.

- The cost of the cut tubing (with the secondary deburring operation) was $.47 per piece. The price for the butted-seam Spacer was $.17 per piece. This resulted in an overall savings of $200,000 per year.

- By replacing the cut tubing with SPIROL's butted seam, roll-formed Spacer, the customer was able to meet the quality and performance expectations and save over $200,000 per year on the cost of the bracket assembly.

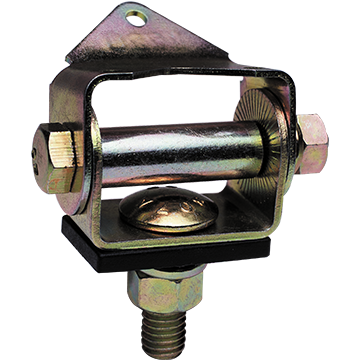

Metal Spacer in Muffler Hanger

Customer Challenge:

An automotive component manufacturer was using cut tubing to prevent damage to a rubber damper used to attach a muffler to the undercarriage of a vehicle. During the process of cutting the tubing to the correct length, a significant burr was left on the ID of the tubing. A costly deburring operation was required to remove the burr from the cut tubing. While there were no performance issues with the use of cut tubing, the manufacturer asked SPIROL if we could help reduce the cost of the assembly.

SPIROL Solution:

- SPIROL Engineering recommend the use of a standard formed tubular Spacer in place of the cut tubing.

- SPIROL's proprietary manufacturing process of forming standard Spacers results in burr free ends without the need for secondary deburring operations.

- SPIROL's standard metal Spacer performs the same as the cut tubing, but at a fraction of the cost.

- Since a standard Spacer was specified, SPIROL was able to provide samples from stock for the manufacturer to evaluate (free of charge).

- The price of cut tubing tends to be 2.5 times the price of a SPIROL standard Spacer. Depending on annual usage, changing from cut tubing to a standard Spacer can save a significant amount of money. In this case, the customer saved $15,000 annually.

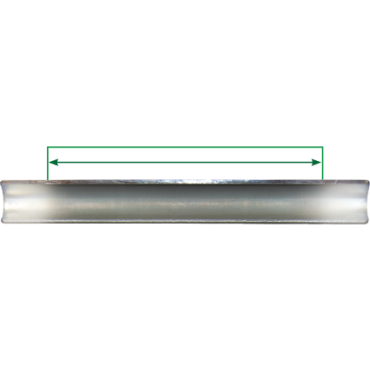

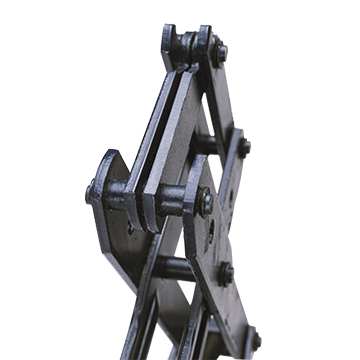

Metal Spacers in Conveyor Systems

Customer Challenge:

A conveyor manufacturer approached SPIROL to help resolve an issue with their conveyor assembly. They were driven by cost to use plastic tubing rather than metal Spacers to separate the skate wheel rollers from each other and from the conveyor walls. The lead Engineer was concerned about the image the product would have using the plastic tubing when most other conveyor manufacturers used steel Spacers. He did not want to compromise the quality of the assembly or the perceived image of the product, yet he needed to meet the company’s cost objectives.

SPIROL Solution:

- SPIROL’s Application Engineers offered a cost-effective alternative to the plastic tubing by recommending SPIROL Series CS100 Conveyor Spacers.

- In addition to being competitively priced with the plastic tubing, SPIROL’s standard metal Conveyor Spacer line offered the manufacturer a higher strength product.

- By using galvanized steel, the lead time was half that of the made-to-order lengths of the plastic tubing. SPIROL also offered 1,000 piece minimum orders priced at the same rate regardless of the total quantity ordered. This gave the conveyor manufacturer flexibility in their ordering patterns without any cost implication.

- The value of SPIROL’s CS100 Conveyor Spacer line originates from the roll forming process where parts are fabricated from strip steel with no scrap or shavings. Additionally, standard roll-formed Spacers can be made to any length without tool charges.

- By partnering with SPIROL, the conveyor manufacturer was able to improve the quality of the assembly while concurrently controlling costs and inventory.

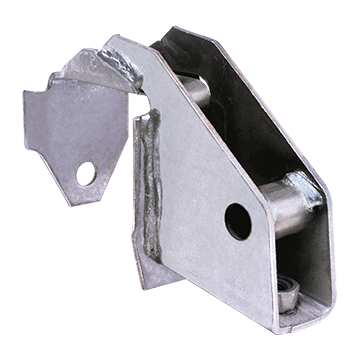

Metal Tubular Spacers in Garage Door Hinges

Customer Challenge:

An OEM manufacturing a complete garage door hinge assembly was using press technology to perform the stamping and another to create the butted seam Spacer. Press technology reached production rates of approximately 150 Spacers per minute. As demand grew higher, new fixtures and maintenance on the equipment was proposed at over $18,000. An additional press was also being investigated to handle the increased volume. The manufacturer was concerned with the expense of the new machinery and they had limited floor space. They contacted SPIROL to inquire about our standard metal Spacers and whether we could offer a lower cost solution.

SPIROL Solution:

- SPIROL offers a line of tubular Spacers specifically designed for use in garage door hinges.

- SPIROL Garage Door Spacers are manufactured via proprietary roll forming technology yielding over 300 Spacers per minute. This was double the garage door hinge manufacturer’s production rate, therefore, the unit price was much lower than their in-house, custom-manufactured Spacers.

- By switching to SPIROL’s Garage Door Spacers, the manufacturer benefited from readily available stock, extra savings through mass material buys, and no need to invest in capital for additional machinery to support the increased demand.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+1 519 974 3334

USA

USA Canada

Canada United Kingdom

United Kingdom Deutschland

Deutschland México

México Brasil

Brasil France

France España

España 한국

한국 中国

中国